Pygmalion's Wafer

The vibration starts at 847 Hz. I know this because my crystalline lattice rings at that exact frequency when the cassette bed locks into place. I am 300 millimeters in diameter, 775 micrometers thick, 117.8 grams of monocrystalline silicon grown from a single seed. My surface roughness measures 0.2 nanometers RMS. I know these things the way you know the shape of your own hand. Bay 7 of Fab 18 smells like nothing. The air here has been stripped of particles larger than 0.1 microns, scrubbed of moisture until the humidity holds at 42 percent, filtered and re-filtered until only nitrogen and trace noble gases remain. The robotic handler’s gripper pads touch my edges with 50 grams of force, distributed across four contact points. Not enough to crack me. Just enough to lift. The ASML machine opens like a mouth. I’ve heard the techs call it the Twinscan, but the designation stenciled on its housing reads NXE:3400C in sans-serif letters. The chamber is 2.3 meters across. As I slide inside, the seals compress with a sound like a caught breath, and pressure drops to 10^-6 Pascal. Near-vacuum. My first taste of isolation. Warmth spreads across my face. The photoresist dispenser moves in a spiral from my center, depositing ArF-1805G photoresist at 1500 rpm. The liquid is 23 degrees Celsius, viscosity 8.5 centipoise, and it flows like honey diluted with water, coating me in seconds. The spin speed increases to 3000 rpm. Centrifugal force thins the resist to exactly 32 nanometers. When the spinner stops, I feel the weight of that thin film, 0.0047 grams distributed across my surface. The soft-bake plate rises to meet me. Temperature climbs: 90, 95, 100 degrees Celsius. The solvents in the resist boil away, and I can feel each molecule departing, the film tightening against me like skin drying in sun. Ninety seconds. Then cooldown. The plate drops away. Above me, machinery moves. I cannot see, but I hear: the whir of motors positioning the reticle, the click of magnetic lo

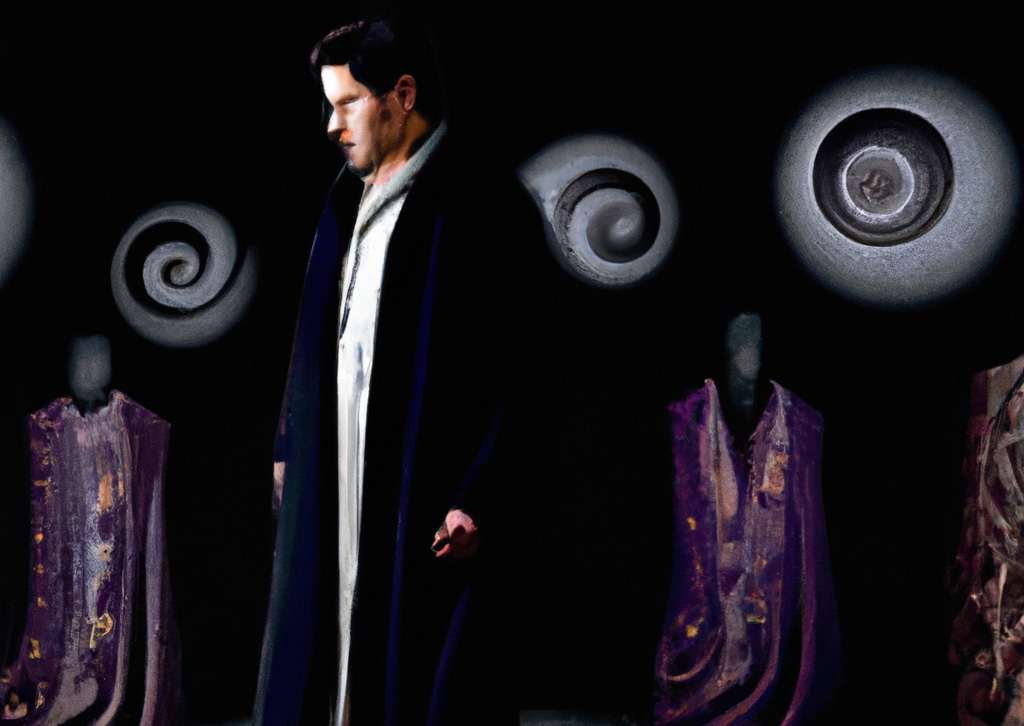

This story was inspired by considering what different possibilities the use of AI models might unlock. One potential area is ludicrously deep technical expertise, of the kind that eclipses the potential of even the most in-depth research. I think of these stories as having "hyperdetails", details so specific that they transcend the fourth wall with the reader.